- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Please Choose Your Language

| Availability: | |

|---|---|

America

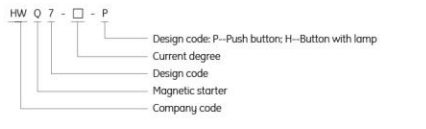

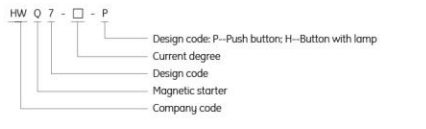

Product Structure Analysis Diagram

Scope of application

Operation and Installation Condition

■Altitude: s 2000m

■Ambient air temperoture-5"C -+40'C , average temperature of 24 hours must below+35'C

■Relative humidty: the maximum temperoture of 40 degrees, the air relative humidity no exceed 50%. at a lower temperature can llw for a higher relative humidty. The wettest month' s average lowest temperature must be below 25'C。 the max relative humidity of that month should not exceed 90%. if humiditychanges as a result of occasional gel generated. should eliminte it. m Istollation position: The nstallation degree of the tit and vertical plane should not exceed 5"

■In a non-explosive hazordous medium. and there is no place in the medium that is sufficient to corrode metals and destroy insulation gases and conductor dust.

■Where there is rain and snow protection and there is no steam.

■Shock vibratione Products should be ntolld and used without severe shake, shock and vibration of the place.

Specifications

■Specifications for magnetic storter (sheet)

■Coll rated control power supply voltage Us can be divded into AC 50Hz or 60H2

■36V, 110V. 220V, 380V.

■Operating condtionr Coll pll-in woltoge is 185%6-11061 Us; Release voltage is (20%6- .7596)Us

| Type | Rated cumet le A | Maxrnuim power dutykW | Matched AC cortoctar type | Matched therrnal reloy | Setting curtent rangeA | ||

| AC-3 | |||||||

| EE0V | 380v | 220V | |||||

| Q7-09 | 9 | 5.5 | 4 | 2.2 | C7-D09/C7s-09 | J7-25 J7s-25 | 0.1-0.16.016-0.25 0.25-0.4,0.4-0.63 0.63~1.1~1.6 1.25-2.1.6-2.5 2.5-4,4-6,5.5-8 |

| Q7-12 | 12 | 7.5 | 5.5 | 3 | C7-D12/C7s-12 | J7-25 J7s-25 | 7-10.9-13 |

| Q7-18 | 18 | 10 | 7.5 | 4 | C7-D18/C7s-18 | 12-18 | |

| Q7-25 | 25 | 15 | 11 | 5.5 | C7-D25/C7s-25 | 17-25 | |

| Q7-32 | 32 | 18.5 | 15 | 7.5 | C7-D32/C7s-32 | 23-32 | |

| Q7-40 | 40 | 18.5 | 18.5 | 11 | C7-D40/C7s-40 | J7-93 J7s-93 | 23~32.30~40 37.50.48-65 55-70.63-80 80-93 |

| Q7-50 | 50 | 22 | 22 | 15 | C7-D50/C7s-50 | ||

| Q7-65 | 65 | 30 | 30 | 18.5 | C7-D65/C7s-65 | ||

| Q7-80 | 80 | 37 | 37 | 22 | C7-D8O/C7s-80 | ||

| 07-95 | 95 | 45 | 45 | 25 | C7-D95/C7s-90 | ||

Scope of application

The starter adopts a protective structure with a protective cover of IP55 and is internally composed of a C7 AC contactor and a J7 thermal overload relay. The entry and exit wiring of the starter adopts the knockout type wiring hole, and the user can selectively knock and connect the four knockout holes according to the wiring requirements. The cover and the base of the starter can be completely separated. and the user is very convenient to install and maintain: the button adopts the XB2 series push button switch assembly to relie the start and stop of the starter. and it will be safe and reliable.

In order to improve the protective performonce of the starter. the starter must be nstalld verically. The mounting screws should be selected according to the size of the mounting hole. The screws should be no less than M5. and spring washers, flot washers and sealing rubber nings should be odded to ensure the fastening of the starter. In addition, the knockout terminal holes should be equipped with corresponding waterproof terminals.

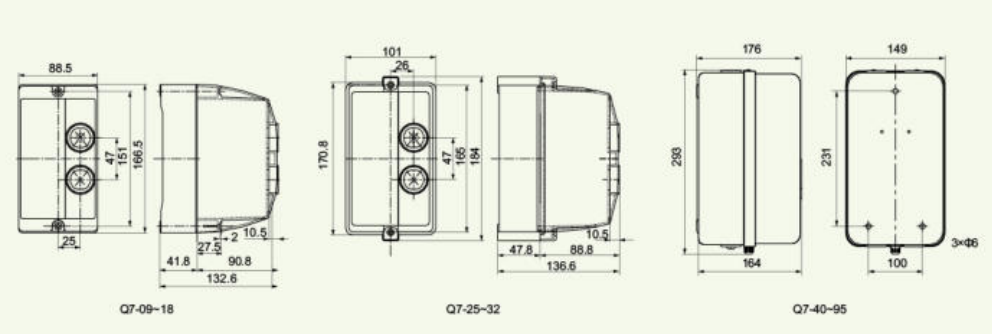

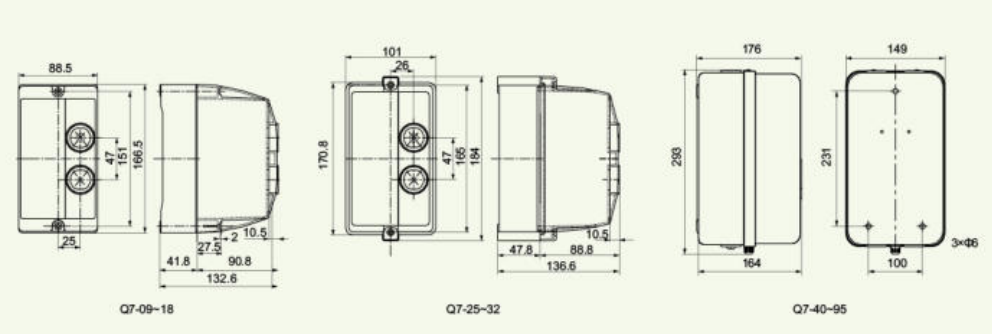

Outline and installation dimensions

Product Structure Analysis Diagram

Scope of application

Operation and Installation Condition

■Altitude: s 2000m

■Ambient air temperoture-5"C -+40'C , average temperature of 24 hours must below+35'C

■Relative humidty: the maximum temperoture of 40 degrees, the air relative humidity no exceed 50%. at a lower temperature can llw for a higher relative humidty. The wettest month' s average lowest temperature must be below 25'C。 the max relative humidity of that month should not exceed 90%. if humiditychanges as a result of occasional gel generated. should eliminte it. m Istollation position: The nstallation degree of the tit and vertical plane should not exceed 5"

■In a non-explosive hazordous medium. and there is no place in the medium that is sufficient to corrode metals and destroy insulation gases and conductor dust.

■Where there is rain and snow protection and there is no steam.

■Shock vibratione Products should be ntolld and used without severe shake, shock and vibration of the place.

Specifications

■Specifications for magnetic storter (sheet)

■Coll rated control power supply voltage Us can be divded into AC 50Hz or 60H2

■36V, 110V. 220V, 380V.

■Operating condtionr Coll pll-in woltoge is 185%6-11061 Us; Release voltage is (20%6- .7596)Us

| Type | Rated cumet le A | Maxrnuim power dutykW | Matched AC cortoctar type | Matched therrnal reloy | Setting curtent rangeA | ||

| AC-3 | |||||||

| EE0V | 380v | 220V | |||||

| Q7-09 | 9 | 5.5 | 4 | 2.2 | C7-D09/C7s-09 | J7-25 J7s-25 | 0.1-0.16.016-0.25 0.25-0.4,0.4-0.63 0.63~1.1~1.6 1.25-2.1.6-2.5 2.5-4,4-6,5.5-8 |

| Q7-12 | 12 | 7.5 | 5.5 | 3 | C7-D12/C7s-12 | J7-25 J7s-25 | 7-10.9-13 |

| Q7-18 | 18 | 10 | 7.5 | 4 | C7-D18/C7s-18 | 12-18 | |

| Q7-25 | 25 | 15 | 11 | 5.5 | C7-D25/C7s-25 | 17-25 | |

| Q7-32 | 32 | 18.5 | 15 | 7.5 | C7-D32/C7s-32 | 23-32 | |

| Q7-40 | 40 | 18.5 | 18.5 | 11 | C7-D40/C7s-40 | J7-93 J7s-93 | 23~32.30~40 37.50.48-65 55-70.63-80 80-93 |

| Q7-50 | 50 | 22 | 22 | 15 | C7-D50/C7s-50 | ||

| Q7-65 | 65 | 30 | 30 | 18.5 | C7-D65/C7s-65 | ||

| Q7-80 | 80 | 37 | 37 | 22 | C7-D8O/C7s-80 | ||

| 07-95 | 95 | 45 | 45 | 25 | C7-D95/C7s-90 | ||

Scope of application

The starter adopts a protective structure with a protective cover of IP55 and is internally composed of a C7 AC contactor and a J7 thermal overload relay. The entry and exit wiring of the starter adopts the knockout type wiring hole, and the user can selectively knock and connect the four knockout holes according to the wiring requirements. The cover and the base of the starter can be completely separated. and the user is very convenient to install and maintain: the button adopts the XB2 series push button switch assembly to relie the start and stop of the starter. and it will be safe and reliable.

In order to improve the protective performonce of the starter. the starter must be nstalld verically. The mounting screws should be selected according to the size of the mounting hole. The screws should be no less than M5. and spring washers, flot washers and sealing rubber nings should be odded to ensure the fastening of the starter. In addition, the knockout terminal holes should be equipped with corresponding waterproof terminals.

Outline and installation dimensions